- Home

- Products

+

- Connectors

+

- Box Header Connectors & Ejector Header Connectors

- Female Header Connectors

- Male Pin Header Connectors & Mini Jumper Connectors

- IC Socket / PLCC Socket / ZIF Socket Connectors

- Wire to Board Connectors & Wire to Wire Connectors

- IDC Connectors

- FFC / FPC Connectors

- Micro Match Connectors

- DIN41612 Connector

- D-Sub Connectors / D-SUB hood

- SIM & Micro SIM & Nano SIM Card Connectors

- Memory Card Connectors

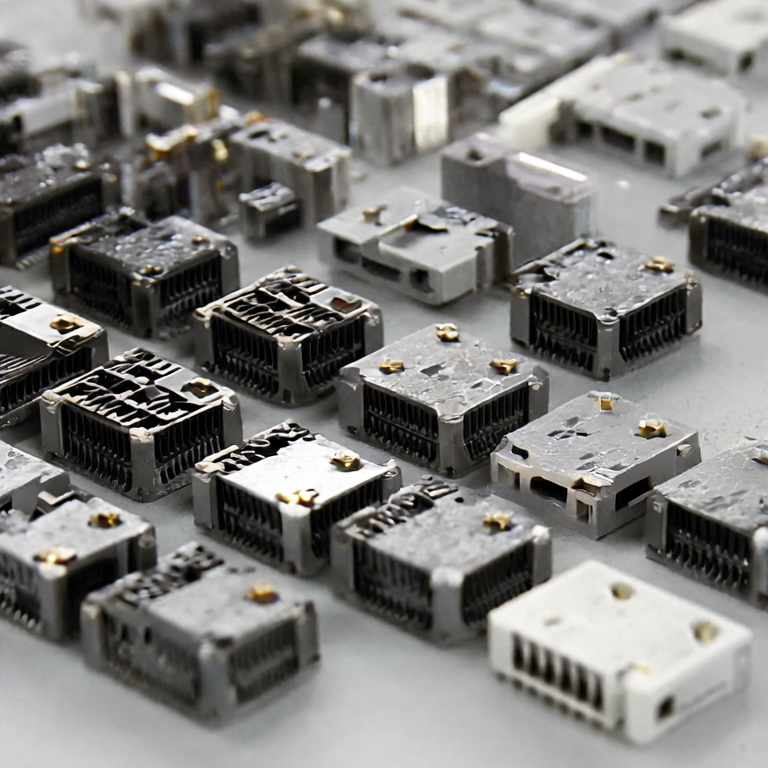

- USB 2.0 / USB 3.0 / USB 3.1 / Type C / Micro USB / IEEE 1394 / Mini USB Connectors

- DVI Connectors & HDMI Connectors

- Y13 / Y17 /Y21 IP68 Waterproof Circular Connectors

- Circular Connectors

- SATA Connectors

- Audio Connectors

- Terminal Blocks

+

- PCB Terminal Block Rising Clamp

- PCB Terminal Block Wire Protector

- Pluggable Terminal Blocks

- Screwless-Spring terminal blocks

- Barrier Terminal Blocks

- Reflow Solder LCP Housing Terminal Blocks

- Fuse lighting terminal blocks

- Feed Through Terminal Blocks and Box

- Miniature Rail-mounted Terminal Blocks

- Insulated terminals

- Non-insulated terminals

- Solder terminals for PCB mount

- Switches +

- Crystals / Oscillators / Resonators +

- Transformers +

- Ethernet Connectors +

- RF Connectors&Antennas +

- Sound sources +

- Connectors

+

- Cross Reference

- Solution

- About RHT

- FAQ

- Download

- News

- Contact Us +

What are the main types of terminal blocks?

Sep. 16, 2025

Sep. 16, 2025In industrial and electronic applications, effective electrical connections are vital. Terminal Blocks play a crucial role in facilitating these connections by providing a reliable interface between wires and electronic devices. As a Terminal Blocks Supplier, we understand the significance of terminal blocks in ensuring safe and efficient power distribution. These components are indispensable in various sectors, including manufacturing, telecommunications, and automation. However, many professionals face challenges such as incorrect wiring, poor connectivity, and safety risks. In this article, we will explore the features of terminal blocks, their types, applications, and advantages in solving these pain points.

What Are Terminal Blocks?

Terminal blocks are electrical connectors where multiple wires can be connected to a single point. They come with a variety of types, including barrier strips, din rail terminal blocks, and plug-in terminal blocks. The primary components of terminal blocks include the housing, which provides insulation, and the conductive metal parts, which are often made of copper or aluminum. The ease of assembly and disassembly makes terminal blocks an essential part of modular electrical systems.

Next, let’s break down the types of terminal blocks.

What Are the Main Types of Terminal Blocks?

Barrier Terminal Blocks: These provide protection against accidental contact and are commonly used in applications that require robust connections.

Din Rail Terminal Blocks: These are designed to be mounted on standard din rails. They are often found in control cabinets and offer modular space-saving solutions.

Plug-in Terminal Blocks: These allow easy plug-in connections, making them suitable for various applications where quick assembly and disassembly are required.

Understanding the differences between these types can help you choose the right terminal block for your specific needs.

Application Scenarios for Terminal Blocks

Terminal blocks find applications in various fields, including:

Manufacturing: In PLC and automation systems, terminal blocks facilitate easy wiring and maintenance, thereby reducing downtime.

Telecommunications: They ensure reliable connections in telecommunication systems, where clear signal transmission is critical.

Building Infrastructure: Terminal blocks can be found in HVAC systems, providing a robust connection for diverse temperature control wiring.

Why Terminal Blocks Are Important

The significance of terminal blocks cannot be overstated. They provide several advantages, including:

Safety: By ensuring reliable electrical connections, terminal blocks minimize short-circuit risks and enhance overall system safety. A well-connected system can reduce electrical failures by as much as 30%, improving operational reliability.

Ease of Maintenance: Modular designs allow for easier troubleshooting and replacement without disrupting the entire system.

Versatility: They can accommodate various wire sizes and types, making them suitable for all kinds of electrical systems.

Next Steps: User Guides and Further Exploration

To maximize the benefits of terminal blocks, it is recommended to go through the user guide. This document provides detailed information on installation procedures, safety measures, and troubleshooting tips.

For those interested in high-quality terminal blocks, we recommend exploring brands known for their reliability, such as RHT. Doing so not only enhances your project\'s integrity but also fortifies the electrical connections you depend on.

FAQs about Terminal Blocks

Q: What is the standard size for terminal blocks?

A: Terminal blocks come in various sizes, but the most common sizes accommodate wire gauges from 8 AWG to 22 AWG.

Q: Can terminal blocks be reused?

A: Yes, terminal blocks can often be reused, especially in plug-in varieties. However, ensure that the condition of the block maintains its insulating and conductive properties.

Q: Are there terminal blocks designed for outdoor use?

A: Indeed, there are weather-resistant terminal blocks designed for external applications, which provide protection against moisture and environmental factors.

Final Thoughts

In conclusion, terminal blocks are a critical component in modern electrical systems for various industries. By choosing the right supplier and type, you can ensure robust, safe, and efficient connections. For a deeper understanding or to try out terminal blocks, consider looking at brands such as RHT, which offer a comprehensive range of products designed to meet your specific needs.

For more information, don\'t hesitate to consult the user guide or reach out to our support team for assistance.